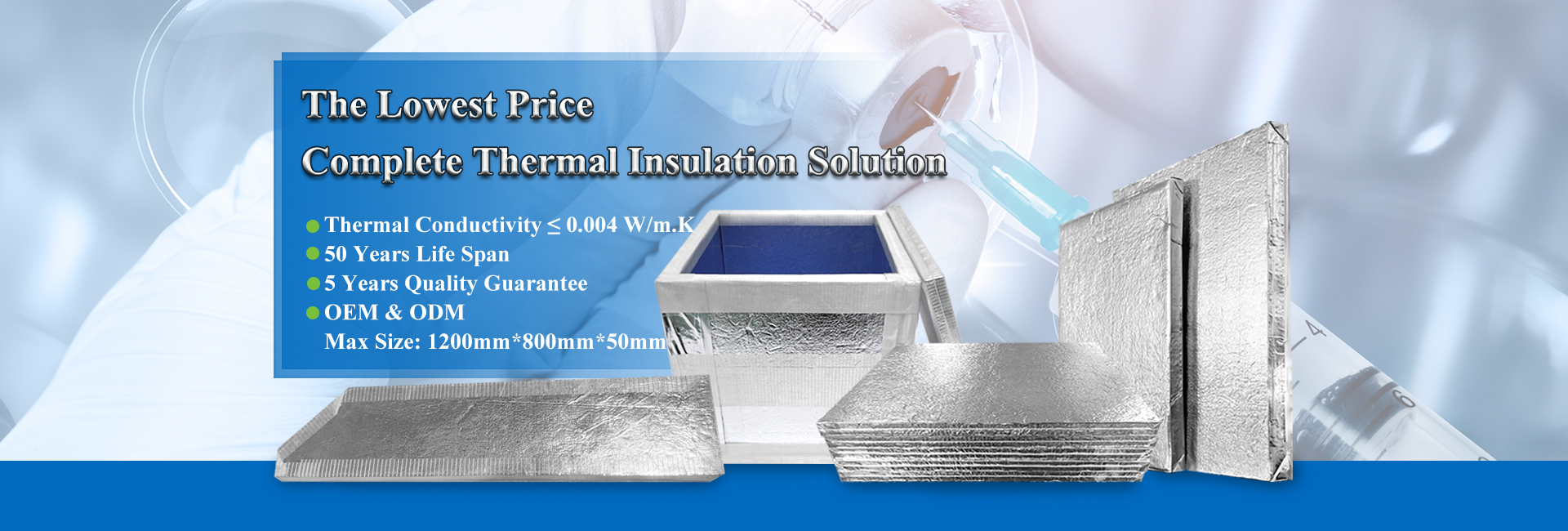

Vacuum insulation panels (VIP) are revolutionizing the field of thermal insulation by delivering superior thermal performance in a compact, lightweight design. These panels are made of a fumed silica core material with an extremely low thermal conductivity (≤ 0.0045 W/mK), providing optimum thermal insulation for a variety of applications. Coupled with its customization in size and shape, VIP is quickly becoming the solution of choice in industries such as pharmaceutical incubators, freezers, vaccine cold boxes for cold chain logistics, ultra-low temperature freezers, and household refrigerators.

At the heart of VIP is a unique core material called fumed silica. Fumed silica is a highly porous substance with excellent thermal insulating properties. Fumed silica particles are dispersed within the vacuum-tight enclosure, forming panels that minimize heat transfer by conduction, convection, and radiation. This innovative design ensures that the VIP maintains a stable, efficient thermal barrier even in demanding environments.

One of VIP's outstanding features is its customization in size and shape. Unlike traditional insulation that requires standard sizes, VIP can be custom-made for specific applications. This flexibility allows the VIP to be seamlessly integrated into a variety of products, enabling manufacturers to increase their performance and efficiency. Custom-sized VIPs can be easily integrated into pharmaceutical incubators, freezers and ultra-low temperature freezers, ensuring precise temperature control critical for preserving sensitive medical supplies and perishable goods.

The lightweight nature of VIP is another advantageous feature that sets it apart from traditional insulation options. The significantly reduced weight of the VIP provides a practical solution for applications where weight constraints are critical, such as cold chain logistics for vaccine cold boxes. Transporting vaccines requires strict temperature control, and VIP offers a lightweight solution without compromising thermal insulation. This feature also proves beneficial in domestic refrigerators, where energy efficiency and space optimization are crucial.

Additionally, VIP exhibits excellent thermal performance with an industry-leading thermal conductivity of ≤ 0.0045 W/mK. This extremely low value ensures minimal heat transfer, which increases energy efficiency and saves costs. VIP effectively reduces energy consumption and carbon footprint, making it a sustainable choice for your insulation needs. By incorporating VIP into their products, manufacturers can provide consumers with energy-efficient solutions consistent with their environmental commitments.

vacuum insulation panels combine the advantages and customization of fumed silica core materials to provide superior thermal insulation properties for a wide range of applications. Its unique design disperses fumed silica particles within a vacuum-tight enclosure, ensuring minimal heat transfer. In addition, VIP size and shape customization capabilities make it ideal for pharmaceutical incubators, freezers, vaccine coolers for cold chain logistics, ultra-low temperature freezers, and household refrigerators. With its lightweight construction and low thermal conductivity, VIP offers energy-efficient solutions that meet the demands of today's industry while prioritizing sustainability.

Post time: Jun-26-2023