Fire Resistance with Fumed Silica Board Manufacturer Building Insulation Material for Industrial and Commercial Applications

We have now numerous great personnel members good at advertising, QC, and working with kinds of troublesome dilemma from the creation course of action for Fire Resistance with Fumed Silica Board Manufacturer Building Insulation Material for Industrial and Commercial Applications, “Change for that improved!” is our slogan, which means “A better globe is before us, so let’s take pleasure in it!” Change for the better! Are you all set?

We have now numerous great personnel members good at advertising, QC, and working with kinds of troublesome dilemma from the creation course of action for Building Insulation Material, Fire Resistance Fumed Silica Board, Fumed Silica Board Manufacturer, All styles appear on our website are for customizing. We meet up to personalized requirements with all solutions of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

Product Features

Fumed silica VIP is consisted of a unique combination, mainly on fumed silica, a nano-porous silica materials. And all the components are highly recyclable.Also fumed silica VIP panels insulate performance up to ten times better than conventional insulation materials.

The VIP’s performance is a result of the inner vacuum. In a vacuum, heat can not travel through the air by conduction or convection. This limited ability for heat to travel in the vacuum is what gives vacuum insulation panels such a high thermal insulating performance and R-value.

Product Details

| Thermal Conductivity [W/(m·K)] | ≤0.008 |

| Thermal Resistance [m·K/W] | ≥4 |

| Density [kg/m3] | 180~240 |

| Puncture Strength [N] | ≥18 |

| Tensile Strength [kPa] | ≥100 |

| Compression Strength [kPa] | ≥100 |

| Surface Water Absorption [g/m2] | ≤100 |

| Expansion Rate After Being Punctured [%] | ≤10 |

| Thermal Conductivity After Being Punctured [W/(m·K)] | ≤0.025 |

| Service Life [years] | ≥50 |

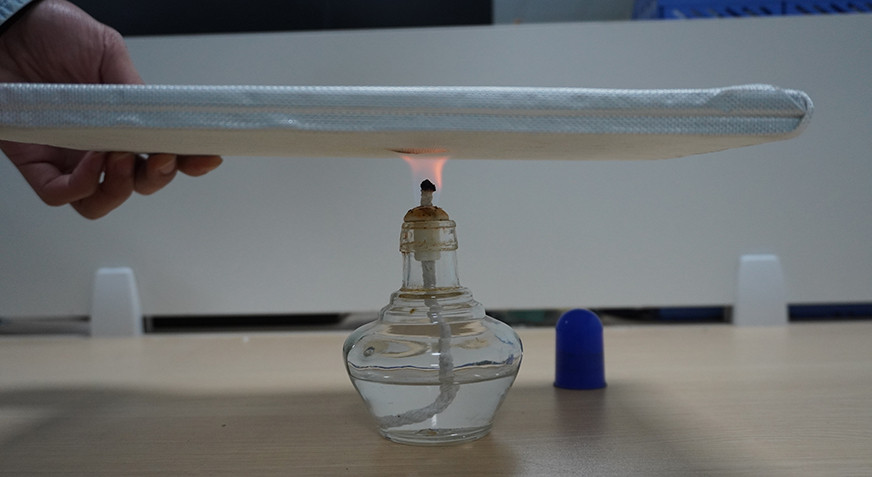

| Fire Resistance | Grade A |

| Working Temperature [℃] | -70~80 |

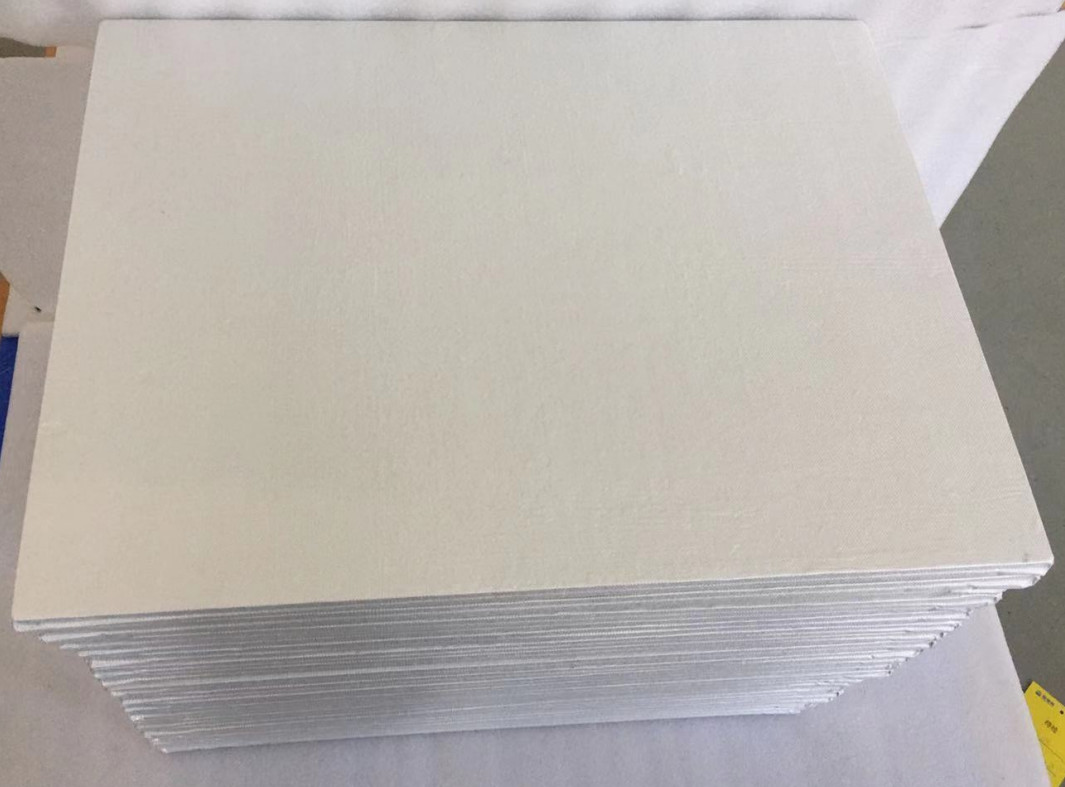

| Size | 300mmx600mmx25mm |

| 400mmx600mmx25mm | |

| 800mmx600mmx25mm | |

| 900mmx600mmx25mm or customized size |

Product Processing

Core material mixing, core producing(Mold Type), core cutting(cutting to customer request size),core packing with non-woven envelop, core drying(removing moisture and debris),vacuum process,first test and leakage inspection, flaps folding,leakage inspection by standing,all test,carton packaging.

Supply Ability:50000 Square Meters per Month

Packaging Details:Strengthened Carton on Pallet

Loading Port: Shanghai, Shenzhen, Guangzhou

Application: building wall, floor, roof

Business Conditions and Terms:

Prices and Delivery Terms: FOB, CFR, CIF, EXW, DDP

Payment Currency: USD, EUR, JPY, CAD, CNY, AUS

Payment Terms: T/T, L/C, D/P D/A, Western Union, Cash

Fumed Silica Board Manufacturer is a leading provider of high-quality insulation boards made from fumed silica, a fine, white, and fluffy powder with exceptional thermal and fire resistance properties. These boards are widely used in industrial and commercial applications, including furnace linings, kiln insulation, and fireproof barriers, to provide reliable and long-lasting insulation and protection against high temperatures and flames. Fumed Silica Board Manufacturer uses advanced technology and manufacturing processes to produce lightweight, durable, and easy-to-install boards that meet the stringent requirements of the construction and manufacturing industries. With Fumed Silica Board Manufacturer, you can unlock unmatched insulation and fire resistance performance and create a safer and more efficient working environment.

Building Insulation Material, Fumed Silica Board Manufacturer, Fire Resistance Fumed Silica Board, All styles appear on our website are for customizing. We meet up to personalized requirements with all solutions of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.