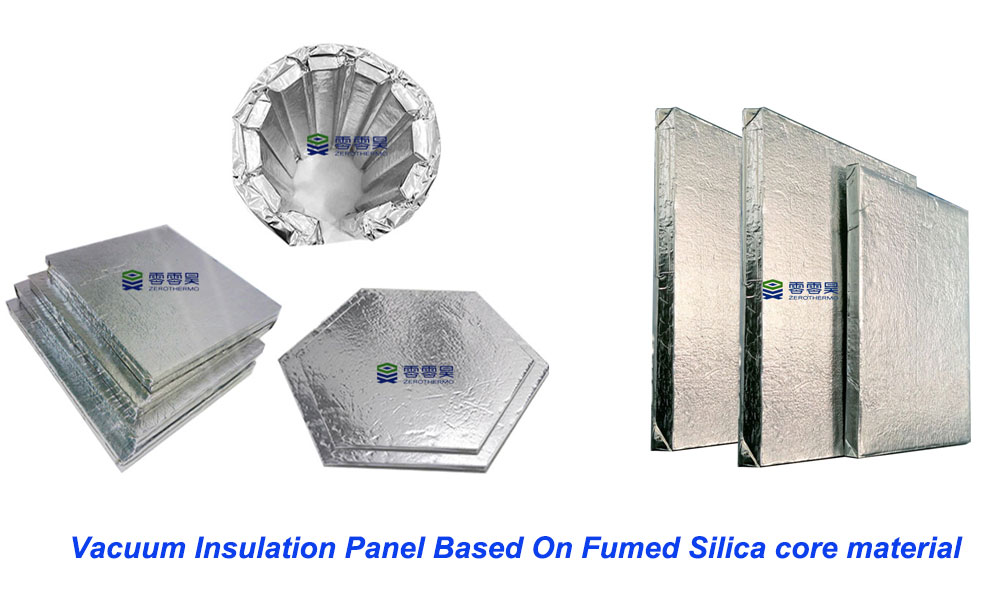

Vacuum Insulation Panels (VIPs) are a relatively new technology in the field of thermal insulation. They are gaining popularity due to their excellent thermal insulation performance and low thickness, which allows for space-saving and energy-efficient applications.VIPs are made of a porous core material, which is enclosed in a vacuum-tight envelope. The envelope is usually made of a thin, high-barrier material that prevents air from entering and reduces thermal conduction. The core material can be made of a range of materials, including fiberglass, silica, and aerogel.

VIPs have been applied in various building applications, including walls, roofs, floors, and HVAC systems. They have an R-value of up to 10 per inch of thickness, which is significantly higher than traditional insulation materials. This means that buildings can be made more energy-efficient, reducing heating and cooling costs and improving indoor comfort. They are particularly useful in applications where space is limited, such as in retrofits, and can help reduce heating and cooling costs.

One of the most promising applications for VIPs is in the retrofitting of older buildings. Many older buildings have poor insulation, resulting in high heating and cooling costs. By adding VIPs to existing walls and roofs, the insulation value can be increased without adding significant thickness to the building envelope. This can result in substantial energy savings for building owners and occupants. Another potential application for VIPs is in the construction of passive houses. Passive houses are designed to be highly energy-efficient and typically require very little energy for heating and cooling. VIPs can help achieve these high levels of energy efficiency by reducing heat loss through the building envelope. This can result in a more comfortable living environment for occupants and lower energy bills.

VIPs are also finding application in refrigeration and cold chain logistics. They can be used to insulate refrigerators, freezers, and shipping containers, ensuring that the contents are kept at the desired temperature.This is particularly important in the transport of temperature-sensitive pharmaceuticals, food products, and other perishables.In the transportation sector, VIPs are being used in the insulation of vehicles, such as airplanes, trains, and cars. VIPs can be used to insulate the walls, floors, and ceilings of these vehicles, reducing the energy needed for heating and cooling. Another emerging application of VIPs is in the infrastructure sector. VIPs can be used to insulate pipes, tanks, and other equipment, reducing energy losses and improving the efficiency of the equipment.

In conclusion, Vacuum Insulation Panels have a wide range of applications in the field of thermal insulation. They are particularly useful in the building, refrigeration, transportation, and infrastructure sectors. VIPs provide superior thermal insulation, which can lead to energy savings, reduced costs, and improved comfort. As technology continues to improve, it is likely that the applications of VIPs will continue to expand.

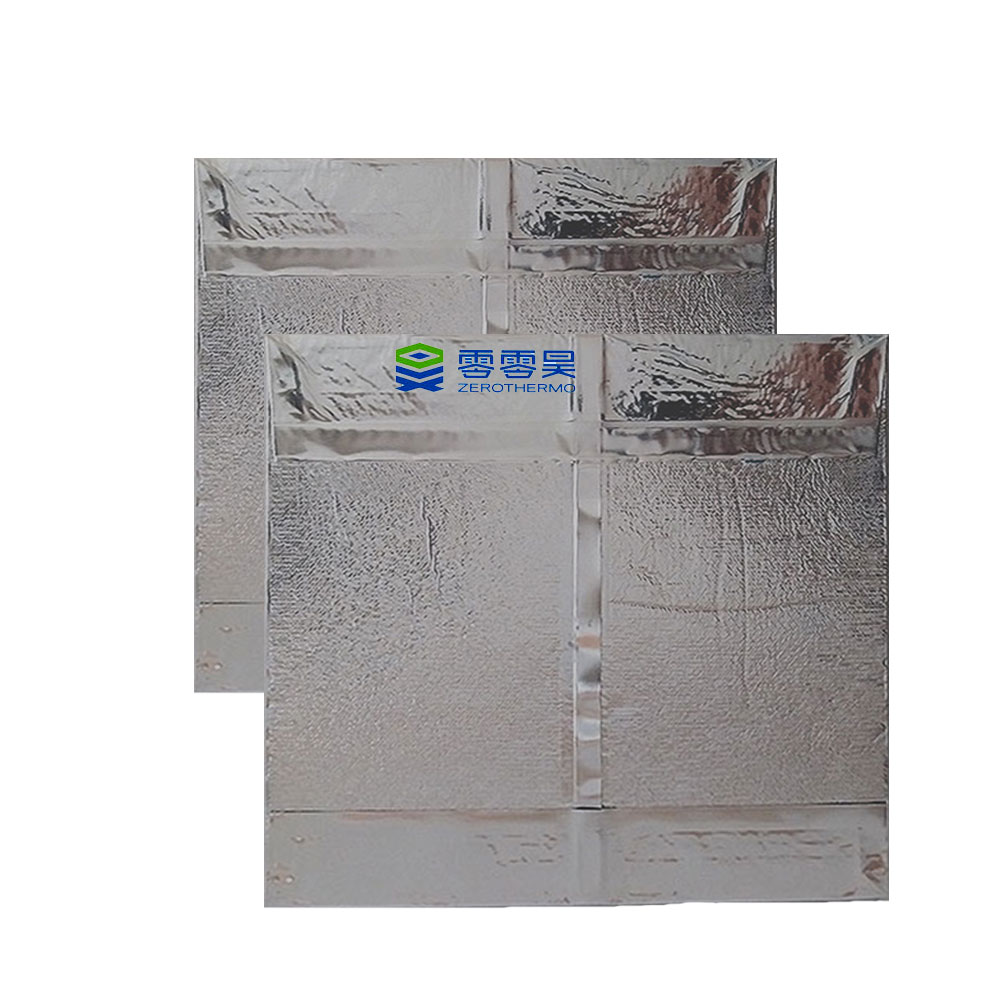

Zerothermo focus on vacuum technology for more than 20 years, our main products : vacuum insulation panels based on fumed silica core material for vaccine, medical, cold chain logistics, freezer, integrated vacuum insulation and decoration panel, vacuum glass, vacuum insulated doors and windows. If you want to learn more information about Zerothermo vacuum insulation panels, please feel free to contact us, also you are welcome to visit to our factory.

Sale Manager: Mike Xu

Phone :+86 13378245612/13880795380

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: Feb-16-2023