Recently, Bill Gates posted a video update to his social media account about his new discoveries in the field of climate change and energy conservation. In the video, Bill Gates talks about the problems of building insulation and energy conservation from the perspective of warm and heat loss in winter. He also mentions that heat comes in and out of windows at this time of year, which not only costs money, but also affects climate change. From the perspective of economic benefits and global climate change, he proposed whether new materials could better solve the problem of heat loss in the window glass, a "weak" link of building insulation. Bill Gates, of course, found the answer he was looking for, and that material was "vacuum glass, because vacuum glass windows have a vacuum sandwich inside that traps heat. What kind of "Black Technology" is this glass? What is vacuum laminated glass? What's the difference between this kind of glass and the double-layer glass we commonly use for doors and windows? With these questions, let's get to know vacuum glass.

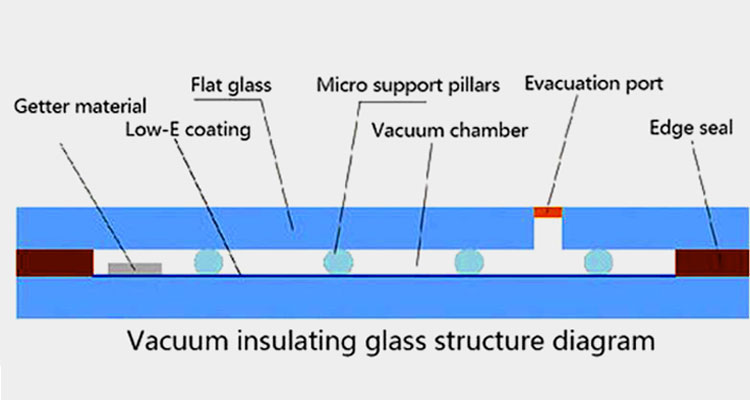

"Vacuum Glass" has completely iterated "hollow glass" in energy-saving technology, which is an important "black technology" to deal with building insulation and global climate change in the future. To put it simply, "vacuum glass" is a small gap space between two pieces of glass. We pump out the air in this space, so as to achieve a "vacuum" state between two pieces of glass. Hollow glass is also composed of two pieces of glass, but between the two pieces of glass filled with air or inert gas.

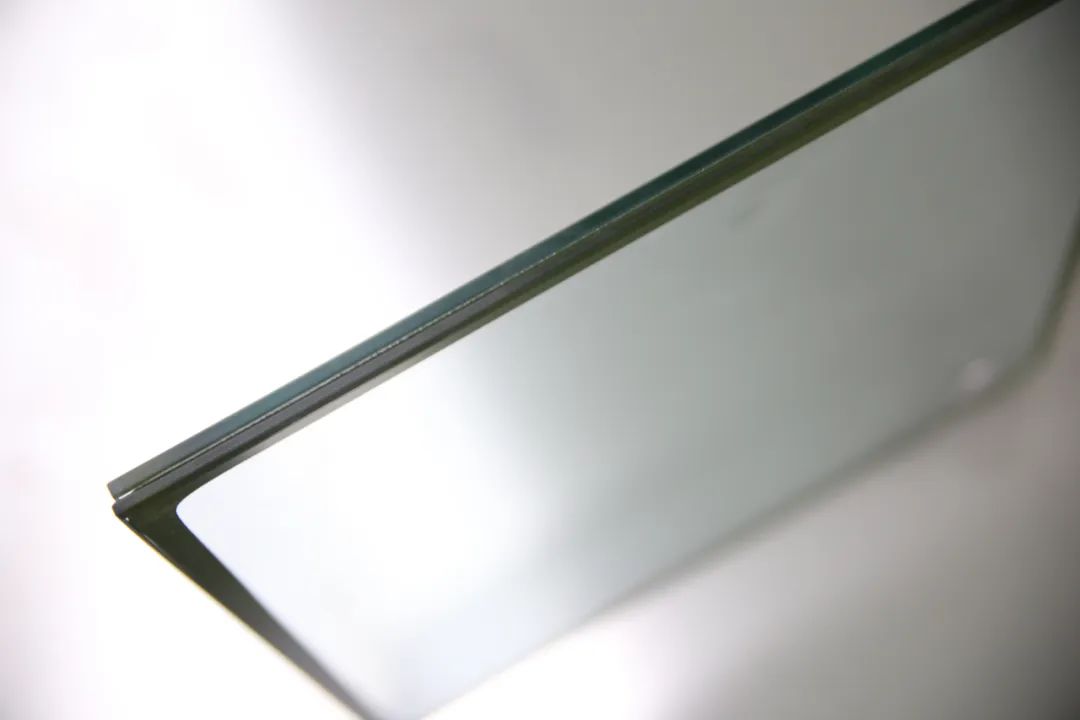

Vacuum glass is a new type of energy-saving glass, it is composed of two or more than two plate glass, glass plates with a diameter of 0.2mm support in a square array distribution, the use of low melting point solder around the two glass sealed, one of the glass has an air outlet, after vacuum exhaust sealed with sealing pieces and low temperature solder to form a vacuum chamber. For the transparent part of the building envelope, it not only assumes the requirement of lighting, but also minimizes the heat gain in summer and heat loss in winter. According to relevant statistics, the influence rate of building transparent envelope structure (doors, Windows, curtain walls, etc.) on building energy consumption reaches 40%.

Different from traditional insulating glass, vacuum glass because there is no gas between the two pieces of glass, vacuum glass effectively isolated heat conduction and heat convection, coupled with low-E glass efficient barrier of thermal radiation, the heat transfer coefficient of vacuum glass can be as Low as 0.5W/(㎡.K), even lower than the three glass two cavity insulating glass. The thermal insulation level of the vacuum glass can achieve similar thermal performance to that of the insulation wall, which also greatly liberates the heat insulation pressure of the window and curtain wall profiles. In addition to the substantial improvement of thermal insulation performance, the noise reduction performance of vacuum glass has also been greatly improved: the weight insulation capacity of single vacuum glass is more than 37dB, and the composite vacuum glass can reach more than 42dB. The use of vacuum glass Windows or curtain walls can effectively isolate the outdoor noise and improve the indoor sound environment.

Zerothermo focus on vacuum technology for more than 20 years, our main products : vacuum insulation panels based on fumed silica core material for vaccine, medical, cold chain logistics, freezer, integrated vacuum insulation and decoration panel, vacuum glass, vacuum insulated doors and windows. If you want to learn more information about Zerothermo vacuum insulation panels, please feel free to contact us, also you are welcome to visit to our factory.

Sale Manager: Mike Xu

Phone :+86 13378245612/13880795380

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: Feb-02-2023