After years of development, the curtain wall industry has shown a rapid development trend in terms of environmental protection, energy saving, cost reduction and efficiency increase. The vigorous development of China's construction industry provides a place for the construction curtain wall industry to show its talents. Building curtain wall is by far the most ideal large-scale public building envelope structure. With the continuous breakthrough and development of curtain wall technology, it is playing an important role in promoting the industrialization of buildings.

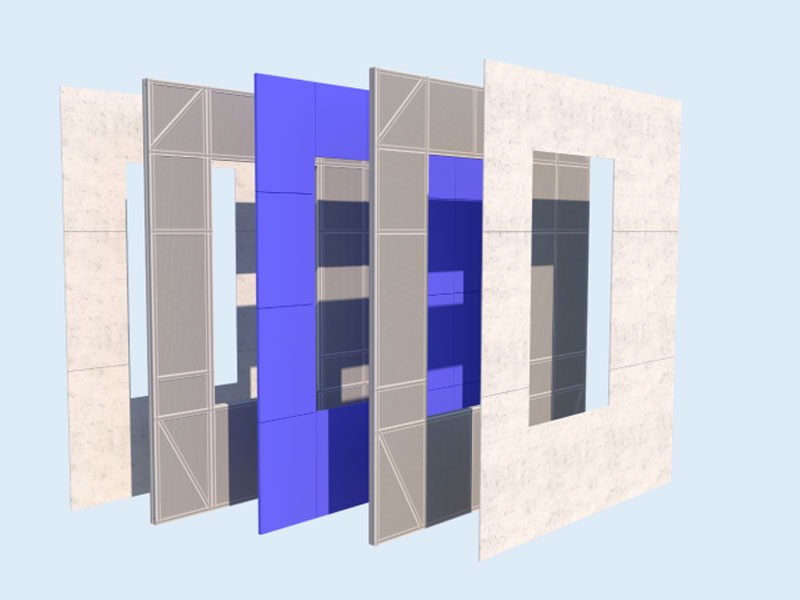

Curtain wall, as the most common form of external structure for the external enclosure of prefabricated buildings, has entered the fast lane of its technological development in recent years, which has promoted the overall development of prefabricated buildings and further promoted the process of building industrialization. As a decorative structure of the building envelope that does not share the stress of the main structure, the curtain wall is composed of a structural frame and inlaid panels, which have a certain displacement capacity relative to the main structure. It is a light-weight wall with decorative effects commonly used in modern large-scale and high-rise buildings.

The building curtain wall Advantages as follows:

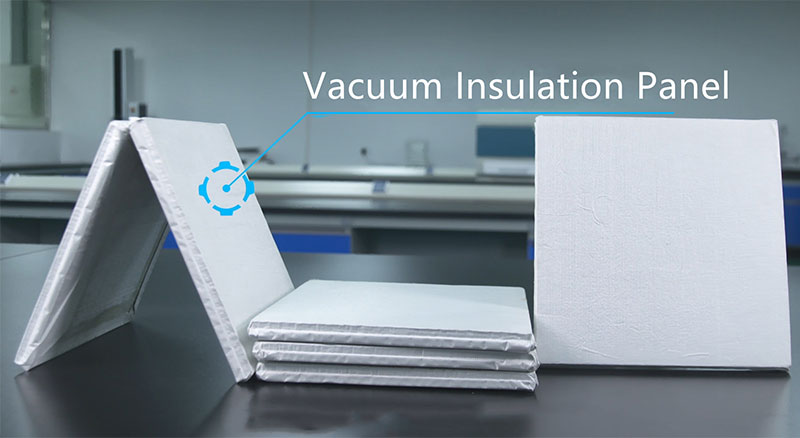

Thinner, Better Performance, More Secure

Thanks to the application of new materials such as vacuum insulation panels, vacuum Insulated Glass. The process of thinning the building curtain wall is particularly significant. The thermal insulation performance of the 2cm-thick vacuum insulation panel basically reaches the effect of the traditional external wall insulation material rock wool 10cm, which greatly reduces the thickness of the wall. , and the wall insulation performance has been significantly improved.

Better Appearance And More Optional Exterior Materials

Unlike traditional buildings that mostly use natural stone, modern curtain wall technology has more materials and colors. The vacuum insulation and decoration integrated panel is made by combining the decorative panel, the adhesive layer and the vacuum insulation panel by using the production and processing method of the factory assembly line. As the thermal insulation decoration material of the curtain wall structure, it greatly improves the thermal insulation performance of the curtain wall while beautifying the appearance of the building, and achieves Class A fire protection. Commonly used ceramic sheets, solid color fluorocarbon decorative panels, metal fluorocarbon decorative panels, colorful stone decorative panels, high-end stone decorative panels, real stone paint texture decorative panels, curtain wall aluminum panels, etc., the surface color can be customized according to architectural design requirement

Much More Convenient Construction Method

Thanks to the prefabricated production of prefabricated building components and prefabricated construction technology, the efficiency of curtain wall construction has been greatly improved compared with traditional building exterior wall construction. Most of the components of the curtain wall are produced and assembled in the factory assembly line. The prefabricated vacuum insulation and decoration integrated wall panel is a series of products applied to the external enclosure structure of prefabricated ultra-low energy consumption buildings. The product is composed of inner and outer decorative panels, vacuum insulation composite insulation layer, tongue-and-groove profiles and installation components, and its main components and materials are all made of Class A fireproof materials.

More environmentally friendly, energy-saving and sustainable development

Modern curtain wall technology, its parts are produced and processed by the workshop, intensive production, and only assembly work is performed on site. Compared with the original cast-in-place operation, it reduces the construction period, reduces construction energy, reduces construction noise, reduces construction waste, reduces environmental pollution, and reduces labor construction costs. After using new insulation materials such as vacuum insulation panels, the building’s operating energy is significantly reduced. consumption.

Zerothermo focus on vacuum technology for more than 20 years, our main products : vacuum insulation panels based on fumed silica core material for vaccine, medical, cold chain logistics, freezer, integrated vacuum insulation and decoration panel, vacuum glass, vacuum insulated doors and windows. If you want to learn more information about Zerothermo vacuum insulation panels, please feel free to contact us, also you are welcome to visit to our factory.

Sale manager: Mike Xu

Phone :+86 13378245612/13880795380

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: Nov-17-2022