Today here we will introduce a heat insulation product called“silica aerogel”, known as the king of heat insulation in the industry. Silica aerogel is a solid material with a nanoporous network structure and filled with gas in the pores. The structure brings no convection effect, infinite shielding plate effect and infinite path effect. The principle of heat insulation lies in the fact that the uniform and dense nanopore and multistage fractal pore microstructure can effectively prevent air convection and reduce heat radiation and heat transfer. Compared with traditional thermal insulation materials, the thermal insulation performance is 2-8 times that of traditional materials, so the amount of silica aerogel is less under the same thermal insulation effect. The replacement cycle of silica aerogel is about 20 years, while the replacement cycle of traditional insulation materials is about 5 years, so the whole life cycle of use cost is lower.

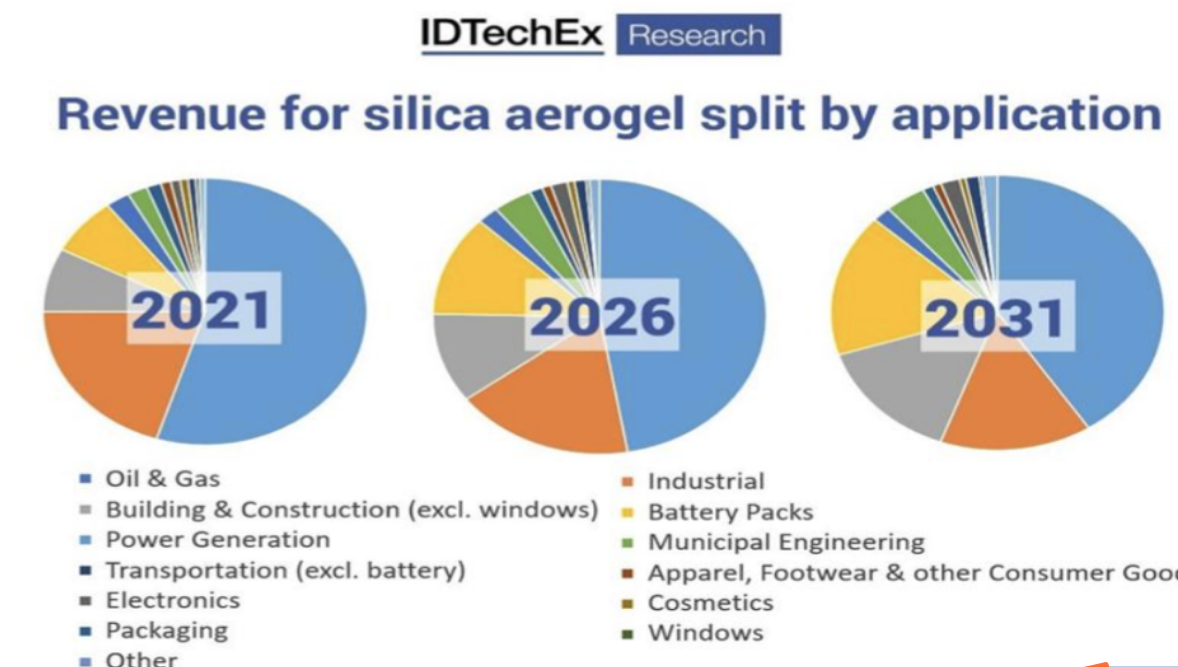

At present, the downstream of silica aerogel is concentrated in industrial pipeline insulation, such as oil and gas projects, industrial insulation, and building construction insulation and other fields, at the same time, for the new energy vehicle battery insulation and other fields to bring technological changes. Due to its super heat insulation and other properties, it was mainly used in aerospace, military and national defense fields in the early days, and then gradually expanded to petrochemical, industrial, construction, transportation, daily use and other fields; It has been extensively studied in many emerging fields such as electrode carrier materials, catalytic materials, sensing materials, nano sterilization materials and drug release.

According to the China Chemical New Materials Industry Development Report, the global silica aerogel market scale is about 870 million US dollars in 2021, and is expected to reach 3.743 billion US dollars in 2030, with a compound annual growth rate of about 17.6% in the next 10 years.

In the aspect of new energy vehicles, silica aerogel can effectively solve the thermal insulation problem of lithium iron phosphate battery at low temperature and the thermal runaway diffusion problem of terpolymer battery at high temperature. It is the preferred material for lithium electric thermal insulation. With the progress of the process and the further scale of the industry, aerogel is expected to gradually replace the traditional insulation materials, especially in the industrial and equipment field speed up. The whole industry will transition from the introduction period to the growth period, and the whole industrial chain is expected to usher in development opportunities

Zerothermo vacuum insulation panels mainly uses glass fiber, aerogel, Fumed silica and polyurethane(PU) as the main core materials. Customers can choose different cored material according to special needs, and we can also customize products based on customers requirement, including the size &shape.

Zerothermo focus on vacuum technology for more than 20 years, our main products : vacuum insulation panels based on fumed silica core material for vaccine, medical, cold chain logistics, freezer, integrated vacuum insulation and decoration panel, vacuum glass, vacuum insulated doors and windows. If you want to learn more information about Zerothermo vacuum insulation panels, please feel free to contact us, also you are welcome to visit to our factory.

Sale Manager: Mike Xu

Phone :+86 13378245612/13880795380

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: Nov-25-2022