Current status of glass for doors, windows and curtain walls

Now compared with the exterior walls of buildings, the doors, windows and curtain walls use a large area of transparent glass, especially for a large number of new non-residential buildings, the curtain wall system has almost become the most important outer protective structure. For the door, window and curtain wall system, the glass area accounts for about 85% of the total system area. It can be said that glass undertakes an important energy-saving task for the building envelope. As the transparent envelope structure of the building, the door, window and curtain wall system naturally has two major defects in order to achieve overall energy saving: one is that the thickness cannot be increased without limit, and the other is that the light transmittance cannot be too low;

from the perspective of energy saving, lighting And insulation is hard to have at the same time. According to research statistics, external windows (including skylights) in building maintenance structures are the main part of energy consumption, and more than 50% of energy consumption is lost through external windows. Therefore, the door, window and curtain wall system has become an energy consumption gap that is difficult for buildings to solve. And the current situation is that the energy-saving solutions we make in the door, window and curtain wall system often focus on how to reduce the energy loss of profiles, and there are not many high-quality solutions to choose from in the selection of glass. As far as the most commonly used insulating glass is concerned, considering Low-E glass, the heat transfer coefficient of insulating glass can reach about 1.8W/(m2.K). The thermal coefficient requirements (generally lower than 1.0W/(m2.K)) naturally require higher standards for door and window profiles. Of course, we have not stopped looking for glass solutions - vacuum glass has become the best choice for building doors, windows and curtain walls to achieve high efficiency and energy saving.

Reasons to Choose Vacuum Glass

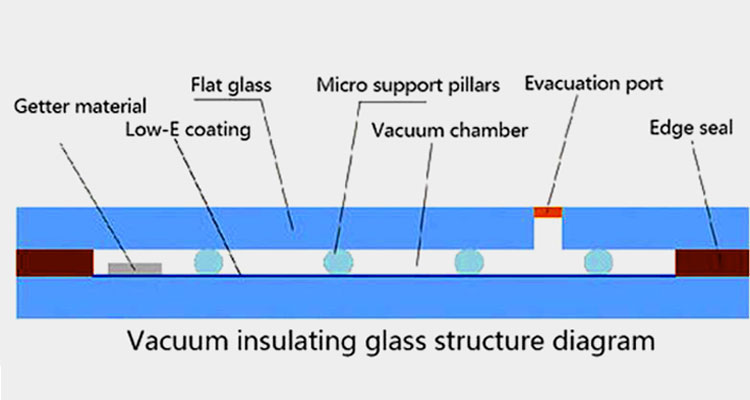

Vacuum glass is a new type of energy-saving glass. Different from traditional insulating glass, vacuum glass is based on the principle of vacuum insulation cup. The two pieces of glass are sealed around, and vacuumed between them, forming a vacuum layer of 0.2mm.

Due to the absence of gas, the vacuum glass effectively isolates heat conduction and heat convection, coupled with the efficient blocking of heat radiation by Low-E glass, the heat transfer coefficient of the vacuum glass alone can be as low as 0.5 W/(m2.K), even It is lower than the insulating glass with three glass and two cavities. The thermal insulation level of vacuum glass can achieve thermal performance similar to that of thermal insulation walls, which also greatly relieves the thermal insulation pressure of door, window and curtain wall profiles. According to the actual inspection by the National Construction Engineering Quality Supervision and Inspection Center, vacuum glass windows are used in cold areas such as Beijing, and the energy saving in winter can reach more than 50%. Therefore, whether it is a glass window or a glass curtain wall, the light-transmitting envelope is no longer the short board of building energy saving, and the energy consumption of the whole building can be significantly reduced, reaching the targets specified for ultra-low energy consumption buildings.

Noise Isolation:

the weight of vacuum glass alone The sound insulation is above 37dB, and the composite vacuum glass can reach above 42dB. The use of vacuum glass windows or curtain walls can effectively isolate outdoor noise and improve the indoor acoustic environment.

As a new glass product, vacuum glass also has advantages that are difficult to replace as follows:

Anti-Condensation:

The super thermal insulation performance of vacuum glass can isolate the indoor and outdoor ambient temperature, and the anti-condensation factor is >75. Even in the cold winter of minus 20℃ outdoors, the temperature difference between the indoor surface temperature of the glass and the indoor air will not exceed 5℃, which is much higher than the dew condensation temperature.

More Comfort:

The super thermal insulation performance of vacuum glass is easy to maintain the constant temperature and humidity in the room. The difference between the indoor surface temperature of the glass and the room temperature is less than 3~5℃, which eliminates the serious cold and heat radiation phenomenon, reduces the temperature gradient in front of the window, and significantly improves the comfort of the indoor environment.

As a new product of door, window and curtain wall glass, vacuum glass can surpass and replace conventional insulating glass in almost all aspects. Under the background that the country has stricter requirements for building energy conservation and people are more and more pursuing the comfort of the living environment, the excellent performance of vacuum glass will be paid attention and accepted by more people, and will become the mainstream door and window glass choice in the future.

Zerothermo technology Co.,Ltd focus on vacuum technology for more than 20 years, our main products : vacuum insulation panels based on fumed silica core material for vaccine, medical, cold chain logistics, freezer, integrated vacuum insulation and decoration panel, vacuum glass, vacuum insulated doors and windows.If you want to learn more information about Zerothermo vacuum glass, please feel free to contact us.

Sale manager: Mike Xu

Phone :+86 13378245612/13880795380

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: Jul-27-2022