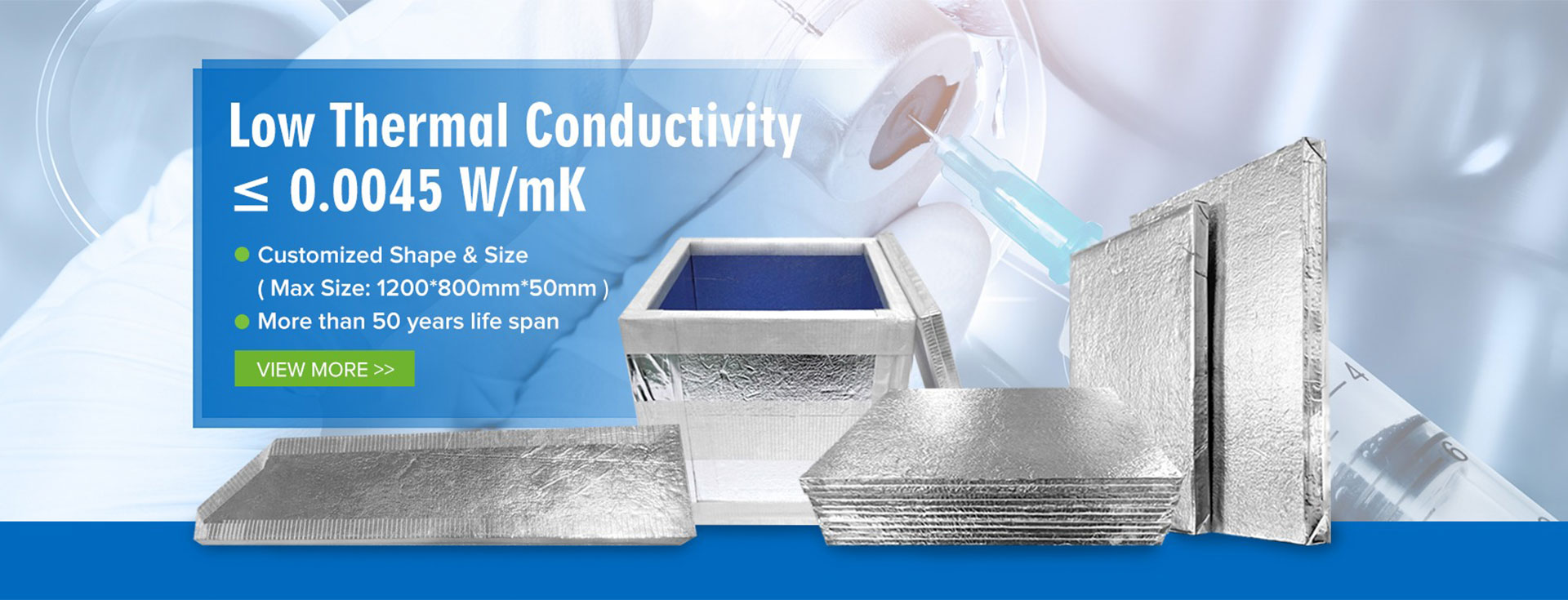

Vacuum insulation panel (VIP) is a new generation of thermal insulation material that has developed rapidly in recent years. It is based on the principle of vacuum insulation. It improves the vacuum of the internal air in the panel and fills the core thermal insulation material to achieve reducing flow and radiation heat exchange. Generally speaking, the heat conduction coefficient of VIP can reach 0.003 ~ 0.004W/(m · k). Under the same thickness conditions, it has 10 times the excellent thermal insulation performance of traditional materials. VIP is mainly composed of three parts: Corematerial, Getter, or Dryer, and diaphragm. The heat transfer of VIP is mainly composed of 4 parts of the core material, the heat conduction of the residual gas inside the VIP, and the circulation of heat spread and radiation heat transfer, which around the maximum reduction of these 4 parts of heat transfer.

VIP panel is Vacuum Insulation Panel. Vacuum insulation panel for the building is developed from the excellent thermal insulation materials used in the device refrigerator. It is one of the vacuum insulation materials. It is composed of the filling core material and the vacuum protection surface layer. It effectively avoids the heat transfer caused by air convection. Therefore Any ODS material has the characteristics of environmental protection and efficiency and energy saving. It is currently the most advanced efficient insulation material in the world. In recent years in China, it has begun to manufacture and adopted the VIP improved refrigerator insulation layer. The entire refrigerator manufacturing seems to have a wave of VIP application tests. In contrast, some foreign developed countries have more than ten years of history of VIP research and use. And the rise of China's manufacturing industry in the twentieth century and the promulgation of national energy conservation policies, VIP, a super -new type of insulation material, is being watched by merchants and has a broad market prospect. VIP is mainly used for insulation heat thermal heat, such as home refrigerators, yacht refrigerators, mini refrigerators, car refrigerators, deep cold freezers, electric water heaters, automatic vending machines, frozen boxes, refrigerated containers, building wall insulation and LNG storage and transportation.

Home appliance refrigerator, yacht (ship) refrigerator or cold storage use VIP insulation panel: 10%to 30%can be saved, and an effective volume of 20%-30%can be increased. In addition to the economic significance, the VIP insulation panel has the advantages of light weight and small volume. The door of the refrigerator door and the freezing box requires light quality and thin walls. VIP insulation panel has great technical and economic significance.

Keep a low temperature refrigerator with cooling materials: When using PU or PF to keep the insulation, the insulation period is only 1 to 2 days; after using VIP insulation material, the insulation period is extended to 4 to 5 days, so that the original items that must be carried out can be changed, which can be changed. Train or train transportation has greatly reduced transportation costs.

Refrigerated thermal insulation box: In the case of the same inside insulation items (1) When using a PU foam, the shape size is 57cm × 50cm × 50cm, the thickness of the insulation layer is 3.8 cm, the interior is 21.8 kg coolant, and the insulation period is 120 h; During the heat insulation, the shape size is 33cm × 46cm × 28cm, the thickness of the insulation layer is 2.5cm, the interior is 7 kg coolant, and the insulation period is 200 h. After using the new VIP material, the volume of the insulation box was reduced by 70%, the coolant decreased by 68%, and the thermal insulation period was extended by 66%. Reduced freight, improved the transportation distance, and the economic effect was obvious.

It is estimated that if the energy -saving transformation of old buildings and the implementation of the energy -saving materials of new buildings will be used in the implementation of new buildings, the emissions of the building C02 can be reduced by 8%alone. In addition, the thickness of the insulation layer is very small and can be recycled. Therefore, VIP consumables are also provinced than ordinary insulation materials. The development of application and building insulation panel can not only efficiently saving energy, but also save a lot of resources. Tone of intensive and environmental protection is of great significance. According to the characteristics of VIP panel's insulation performance and the thickness of the insulation layer required, if it is applied in the building insulation system in cold areas, it will display a large advantage.

In Harbin at an average temperature of one 20 ° C in winter, the energy -saving building with the insulation panel will bid farewell to the traditional 49 wall building or ordinary thick insulation wall building to easily reach the high temperature protection value, and the lighting quality and observation of this thin wall energy -saving building Scenic field of view will be greatly better than thick wall buildings. Because the thin walls will also make house developers more profit, all these factors will undoubtedly have a positive impact on the development of low energy consumption buildings in the cold area north of the Yangtze River Basin in my country.

Zerothermo focus on vacuum technology for more than 20 years, our main products : vacuum insulation panels based on fumed silica core material for vaccine, medical, cold chain logistics, freezer, integrated vacuum insulation and decoration panel, vacuum glass, vacuum insulated doors and windows. If you want to learn more information about Zerothermo vacuum insulation panels, please feel free to contact us, also you are welcome to visit to our factory.

Sale Manager: Mike Xu

Phone :+86 13378245612/13880795380

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: Dec-01-2022