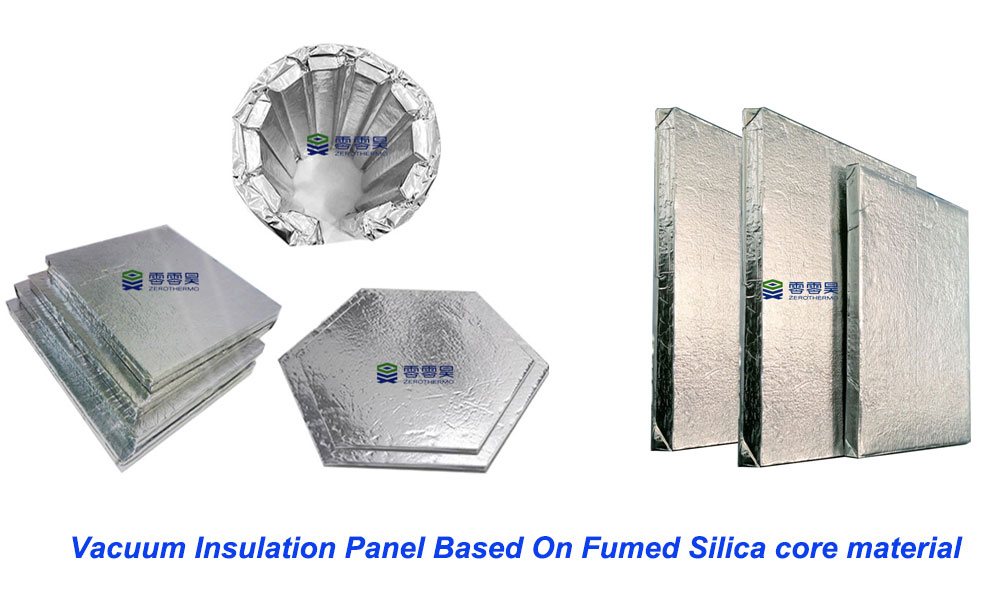

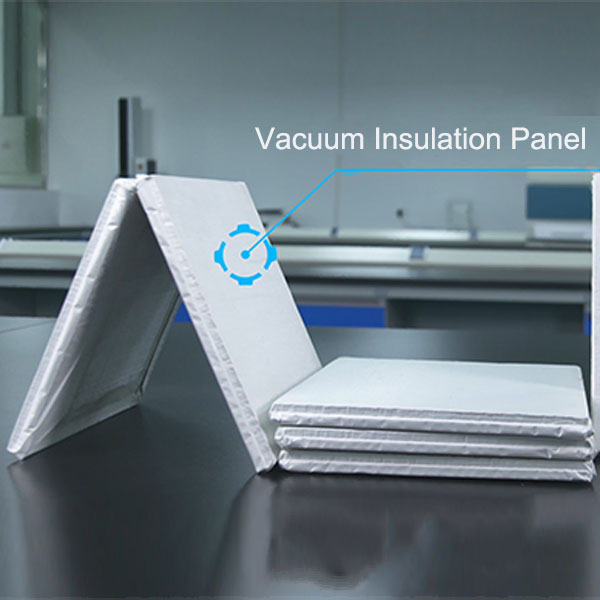

As a new type of high-efficiency thermal insulation material, Vacuum Insulation Panel (VIP board) has the characteristics of low thermal conductivity, small size, light weight, fire prevention, environmental protection and no pollution. Compared with traditional thermal insulation materials, the thermal conductivity of VIP board is only 1/6 or even lower than that of traditional thermal insulation materials, and its thickness is only 1/5~1/10 of ordinary materials, and the VIP panel does not use ozone-depleting layers in the production process. It has the dual advantages of green environmental protection, safety and energy saving, and achieves the purpose of saving space. It is an ideal thermal insulation material, suitable for space constraints and thermal insulation performance requirements.

The light and thin characteristics of vacuum insulation panels also benefit from this. The mass per unit area is less than 15kg/㎡, and the thickness is generally 10-50mm, which can meet the different energy-saving requirements of various regions of the country. Compared with many insulation materials on the market, it can be said to be very good. It is thin and light, which also makes it possible to reduce the area of the insulation layer, do not take up space, improve the room rate, and lower the cost in general. In addition, the vacuum insulation panel also has the core performance of A-class fireproof, moisture-proof and waterproof, safety and environmental protection, and meets all building application requirements.

The vacuum insulated panel is mainly made of inorganic materials, which integrates high-tech technologies such as nano-microporous structure technology, high vacuum technology, and anchoring patent technology. , The thermal insulation performance is very good.

With the rapid development of my country in recent years, the pressure of excessive energy consumption and environmental pollution has increased. Only by taking effective measures can the stumbling blocks in the development process be solved. The importance of energy-saving supply diversification and the application of renewable energy is imminent. In order to ensure the thermal insulation effect, increasing the thickness of the material also means that the unit weight and cost will increase. This approach is uneconomical, difficult to construct, and reduces system security. A kind of thermal insulation material that is both efficient and light and thin is very necessary, so VIP boards have begun to be widely used

Building Vacuum Insulation Panels application advantages:

1. When used in buildings, the VIP board can obtain an effective area. The maximum effective area can be obtained when the building size is fixed.

2. The application of VIP board can reduce the step height between the thermal insulation building room and the terrace and improve the comfort.

3. The application of VIP panels can ensure the construction of thermally insulated floors and ceilings within limited height dimensions.

4. VIP panels can provide satisfactory thermal insulation for gabled buildings with only one small roof.

Zerothermo focus on vacuum technology for more than 20 years, our main products : vacuum insulation panels based on fumed silica core material for vaccine, medical, cold chain logistics, freezer, integrated vacuum insulation and decoration panel, vacuum glass, vacuum insulated doors and windows. If you want to learn more information about Zerothermo vacuum insulation panels, please feel free to contact us, also you are welcome to visit to our factory.

Sale manager: Mike Xu

Phone :+86 13378245612/13880795380,

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: Sep-01-2022