After several discussions, demonstrations and tests of the construction plan by the expert group, the architectural design plan of the R&D building of the Zerothermo production base was finalized now.

At present, domestic building energy consumption accounts for up to 40%, and most buildings are high-energy-consumption buildings. The design concept of zero-energy building is to maximize the use of natural energy, reduce environmental damage and pollution, achieve the purpose of zero fossil energy use, and realize basic recycling of energy demand and waste treatment. Zero-energy buildings provide a comprehensive solution for the sustainable development of urban buildings.

Relying on its own zero-energy building technology system solutions and vacuum energy-saving technologies and products, the R&D building of the zero-energy production base that Zerothermo has built is equipped with "steel structure prefabricated buildings", "Samsung green buildings", "zero carbon and zero energy" Three technical characteristics of "consumption building", adopting a number of leading building energy-saving technologies:

As the technological crystallization of building industrialization, prefabricated buildings represent the most advanced form of future building development. By adopting the construction form of prefabricated buildings, the standardization of building design, production and construction is realized, which is conducive to improving the quality of buildings.

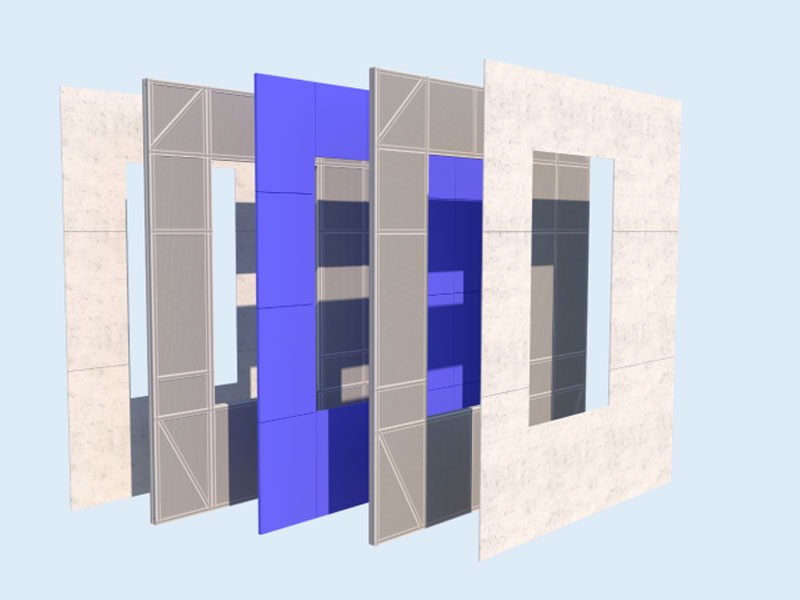

The outer protective structure of the east and west facades of the R&D building adopts metal surface vacuum insulation curtain wall panels, and adopts a component-type curtain wall system. Through specially designed installation components and tongue-and-groove profiles arranged on the end faces of the wall panels, it is connected with the curtain wall keel to independently form the building envelope. body. The wall structure is simple, the installation is quick, the replacement is convenient, and the thermal insulation and decoration are completed in one installation. The unique sealing system is adopted for the joints of the slabs to ensure that the watertightness, airtightness and thermal insulation of the wall fully meet the requirements of ultra-low energy consumption buildings (passive houses), the heat transfer coefficient can reach 0.15W/(㎡·K), and the fire resistance can reach A class.

The transparent part of the envelope structure of Zerothermo R&D building adopts vacuum glass doors, windows and curtain wall systems, heat-insulating aluminum profiles and composite vacuum glass. The thickness of the composite vacuum glass is only 30mm, the heat transfer coefficient can reach below 0.5W/(㎡·K), and the visible light transmittance is more than 65%, and its thermal insulation performance is greatly improved compared to the common insulating glass. The heat transfer coefficient K value of vacuum glass doors, windows and curtain wall systems is less than 1.0W/(㎡·K), and the thermal insulation performance is more than 2-4 times that of the traditional structure, which effectively reduces the overall energy consumption of the building and contributes 20% to building energy conservation. . At the same time, it has strong sound insulation performance, and the weighted sound insulation volume is more than 40dB.

Roof and Wall Facade Photovoltaic BIPV Technology

The roof of the R&D building adopts BIPV technology, the combination of photovoltaic power generation and vacuum insulation roof panel, on-site assembly installation, vertical seam waterproof, cold-break bridge and other unique sealing connection structures to ensure the waterproof, thermal insulation and air tightness of BIPV vacuum insulation roof system. Passive ultra-low energy building standard requirements.

According to estimates, the designed installed capacity of photovoltaic power generation equipment in the R&D building of Zerothermo production base can reach 232kWp, which can generate about 140,000 kWh of electricity when converted into annual power generation, while the annual normal operation energy consumption of the R&D building only needs about 50,000 kWh. The remaining electricity can be integrated into the grid for social use.

Zerothermo focus on vacuum technology for more than 20 years, our main products : vacuum insulation panels based on fumed silica core material for vaccine, medical, cold chain logistics, freezer, integrated vacuum insulation and decoration panel, vacuum glass, vacuum insulated doors and windows. If you want to learn more information about Zerothermo vacuum insulation panels, please feel free to contact us, also you are welcome to visit to our factory.

Sale manager: Mike Xu

Phone :+86 13378245612/13880795380,

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: Aug-30-2022