Your Premier VIP Insulation Panels Manufacturer for Top-Tier Thermal Performance

As a way to present you with ease and enlarge our enterprise, we also have inspectors in QC Staff and assure you our best company and product for Your Premier VIP Insulation Panels Manufacturer for Top-Tier Thermal Performance, In purchase to expand our international market, we mainly provide our oversea prospects Top quality performance items and assistance.

As a way to present you with ease and enlarge our enterprise, we also have inspectors in QC Staff and assure you our best company and product for Thermal Performance vacuum Panels, vip insulation panels, Vip Insulation Panels Manufacturer, We’re seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

Product Features

Fumed silica VIP is consisted of a unique combination, mainly on fumed silica, a nano-porous silica materials. And all the components are highly recyclable.Also fumed silica VIP panels insulate performance up to ten times better than conventional insulation materials.

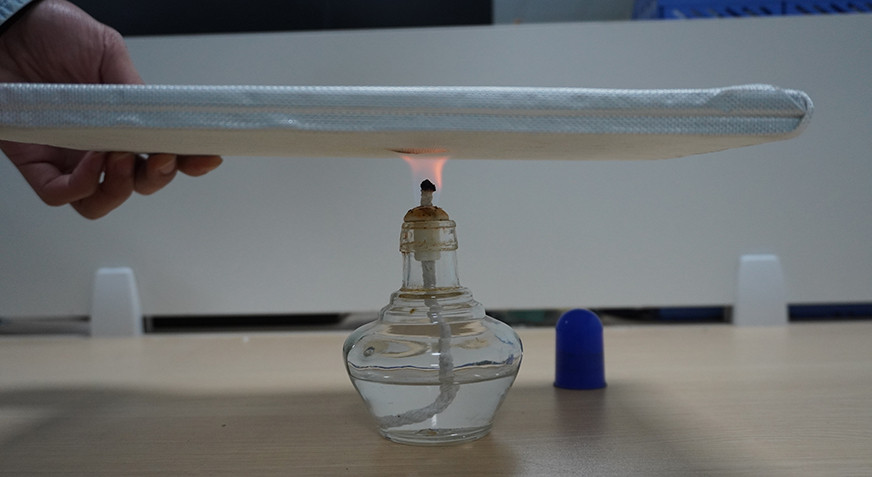

The VIP’s performance is a result of the inner vacuum. In a vacuum, heat can not travel through the air by conduction or convection. This limited ability for heat to travel in the vacuum is what gives vacuum insulation panels such a high thermal insulating performance and R-value.

Product Details

| Thermal Conductivity [W/(m·K)] | ≤0.008 |

| Thermal Resistance [m·K/W] | ≥4 |

| Density [kg/m3] | 180~240 |

| Puncture Strength [N] | ≥18 |

| Tensile Strength [kPa] | ≥100 |

| Compression Strength [kPa] | ≥100 |

| Surface Water Absorption [g/m2] | ≤100 |

| Expansion Rate After Being Punctured [%] | ≤10 |

| Thermal Conductivity After Being Punctured [W/(m·K)] | ≤0.025 |

| Service Life [years] | ≥50 |

| Fire Resistance | Grade A |

| Working Temperature [℃] | -70~80 |

| Size | 300mmx600mmx25mm |

| 400mmx600mmx25mm | |

| 800mmx600mmx25mm | |

| 900mmx600mmx25mm or customized size |

Product Processing

Core material mixing, core producing(Mold Type), core cutting(cutting to customer request size),core packing with non-woven envelop, core drying(removing moisture and debris),vacuum process,first test and leakage inspection, flaps folding,leakage inspection by standing,all test,carton packaging.

Supply Ability:50000 Square Meters per Month

Packaging Details:Strengthened Carton on Pallet

Loading Port: Shanghai, Shenzhen, Guangzhou

Application: building wall, floor, roof

Business Conditions and Terms:

Prices and Delivery Terms: FOB, CFR, CIF, EXW, DDP

Payment Currency: USD, EUR, JPY, CAD, CNY, AUS

Payment Terms: T/T, L/C, D/P D/A, Western Union, Cash

A VIP Insulation Panels Manufacturer specializes in creating high-performance insulation panels that utilize Vacuum Insulation Panels (VIPs) to provide exceptional thermal insulation. VIPs consist of a core material, such as fumed silica or glass fibers, which is enclosed in a gas-tight envelope and evacuated to create a vacuum. This results in an insulation material that is up to ten times more effective than traditional insulation materials, making VIP insulation panels ideal for a wide range of applications, including refrigeration, building construction, and transportation. A VIP Insulation Panels Manufacturer is an expert in creating these panels to meet the specific needs of their customers, offering a variety of options in terms of size, thickness, and performance. Their products are designed to provide optimal thermal performance, while also being durable, cost-effective, and easy to install.

China OEM Vip Insulation Panels Manufacturer, Thermal Performance vacuum Panels, VIP Insulation Panels, We’re seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.